Okay, let me tell you about my recent experience with becoming an aerosol operator. It all started when I saw this job posting online. It sounded interesting, and the pay was decent, so I thought, “Why not?” I applied, got an interview, and, surprisingly, they hired me on the spot.

The first few days were all about training. We learned about the different parts of an aerosol can. You’ve got your can, the stuff inside (which they call the product), the propellant (that’s what makes it spray), and this little valve thingy. Some have a tube inside too, others don’t. On top, you have the button you press (the actuator) and a cap to keep it from spraying accidentally.

- The can

- The product

- The propellant

- A valve

- An actuator

- A dust cap

They showed us the whole process of how these things are filled. Picture this: empty cans coming down a line, getting inspected, then filled with the product and the propellant. Next, the valve is put in, and the can is sealed up, or “crimped,” as they call it. Finally, they check for leaks.

The training wasn’t just about the technical stuff. We had to take this 8-hour course on using Oleoresin Capsicum (OC) aerosol projectors. Turns out, that’s just a fancy way of saying pepper spray. We learned how to use it properly, how to avoid getting sprayed ourselves, and all the legal stuff that comes with it. It was pretty intense, but necessary, I guess.

They told us about how aerosol cans are actually dangerous goods. I didn’t know that. They are class 2 and you have to be careful with them. You know how you shake them before using them? That is to mix the ingredient with the propellant and solvent. They told us that it is dangerous because of all the parts, not just the ingredient.

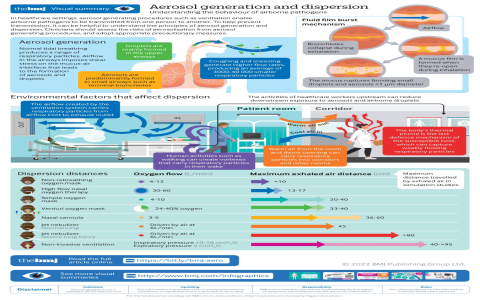

The trainer was going on and on about how aerosol is a type of gas mixture, and how the small particles are all evenly spread out in the air. He was saying that aerosols can come from natural things like fog or human causes, but most of the time when people say aerosol they mean the small particles that are in the air.

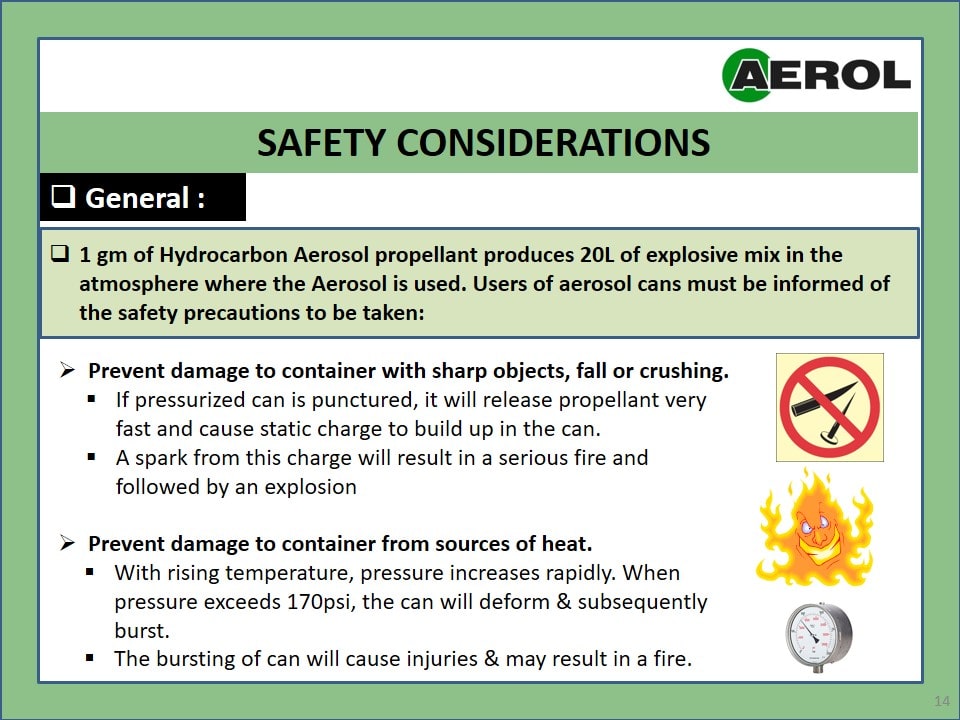

Safety Training

We also got some safety training. They emphasized that aerosol cans are considered “Class 2 Dangerous Goods,” so we need to handle them with care. I never thought of them as dangerous before, but I guess with all that pressure and the chemicals inside, it makes sense.

After all that training, I finally got to work on the production line. It was pretty cool seeing the whole process in action. My job was mostly monitoring the machines and making sure everything was running smoothly. Sometimes I had to do some quality control checks, like making sure the cans were filled correctly and the valves were working.

It’s not the most glamorous job, but it’s honest work. Plus, I learned a lot about aerosols and how they’re made. I never thought I’d be an aerosol operator, but here I am. It just goes to show, you never know where life will take you.